Add to Cart

Polyurethane mould glue

Two component Polyurethane Pre-polymer for the shoe mould

Description

This system materials is Bi-component. A is polyol component, and B is MDI-terminated pre-polymers.

Application

This system material is used to produce various Pu mould, such as shoe mould, concrete mould tec. It can substitute silicone rubber to produce “artificial culture stone”.

Characteristic

It has excellent processing properties, cured under room temperature, short demould time, and the color can be changed by adding pigment. The final products are transparent which enjoy good abrasion resistance, water resistance, good resilience. The hardness is in the 40 to 90 shore A hardness range.

Characteristics of components & Physical properties

| B | Type | B20 | B30 | B55 | B68 | B70 | B80 | B85 | B90 | B93 | B95 |

| Appearance | Colorless or light yellow transparent liquid | ||||||||||

| Viscosity(mPa·s/30℃) | 1500±150 | ||||||||||

| A | Type | A20 | A30 | A55 | A68 | A70 | A80 | A85 | A90 | A93 | A95 |

| Appearance | Light yellow transparent liquid | ||||||||||

| Viscosity(mPa·s/30℃) | 560±200 | ||||||||||

| Ratio A:B(mass ratio) | 1:1 | 1:1 | 1:1 | 100/40 | 1:1 | 1:1 | 1:1 | 1:1 | 1:1 | 1:1 | |

| Operating Temperature(℃) | 30~60 | ||||||||||

| Gel Time(min/30℃)* | 20-50 | 20-50 | 20-50 | 1-2 | 15-30 | 10-20 | 8-15 | 30-60 | 45-55 | 45-55 | |

| Appearance of final products | Light yellow elastomer | ||||||||||

| Hardness(Shore A) | 23 | 33 | 55 | 68 | 70 | 80 | 85 | 90 | 93 | 95 | |

| Tensile strength(Mpa) | 2 | 3 | 10 | 15 | 10 | 16 | 20 | 20 | 22 | 25 | |

| Elongation at break(%) | 300 | 300 | 566 | 530 | 560 | 550 | 540 | 500 | 357 | 324 | |

| Tear strength(kN/m) | 15 | 20 | 58 | 56 | 56 | 65 | 80 | 85 | 92 | 95 | |

| Rebound(%) | 55 | 50 | 47 | 40 | 46 | 45 | 45 | 42 | 42 | 45 | |

| Specific gravity(25℃)(g/ cm3) | 1.03 | 1.05 | 1.06 | 1.07 | 1.07 | 1.07 | 1.07 | 1.09 | 1.09 | 1.09 | |

Mixing and curing

A component ------------------------------------------------------ 100

B component -------------------------------------------------------------------------- as the recommended ratio

Mix temperature (A/B)/ ℃ ----------------------------- 30~60

Mould temperature ℃ --------------------------------------------------------- 30

Gel time (min) ------------------------------------------------------------- as the above data

Postcure, hours/(℃) ----------------------------------------------------- 16 at 100

Storage

Store in a cool and dry place,If you can’t use it up at one time, Pls fill nitrogen gas and then seal it.

Shelf life

The storage time of original packing is 6 month at the above condition from the date of production.

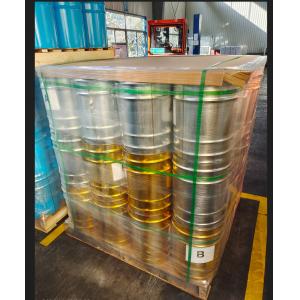

Packing

20kg or 200kg per steel drum

Operation by manual

1.Take certain A component to make reserve.

2. Calculate B component to make reserve.

3. Pour B component to A component and stir evenly.

4. Cast the mixture of step 3 to the mould.

6. Open the mould when the product is hard.

7. Post cure 16 hours at 100℃.

Note: The mixture in the step 3 can be vacuumized to get rid of bubble.

Operation by casting machine

1. Put some A component into A tank, vacuumize to make reserve.

2. Put some B component into B tank, vacuumize to make reserve.

3. Cast the two materials according the ratio to the mould.

4. Open the mould when the product is hard.

5. Post cure 16 hours at 100℃.

Safety

Use in a well ventilated area. Avoid contact with skin using protective gloves and protective clothing. Repeated or prolonged contact on the skin may cause an allergic reaction.

Eye protection is extremely important. Always use approved safety glasses or goggles when handling this product.

If Contact Occurs:

Skin: Immediately wash with soap and water. Remove contaminated clothing and launder before reuse. Seek medical attention if allergic reactions occur.

Eyes: Immediately flush with water for at least 15 minutes, contact a physician.

Ingestion: If swallowed, contact a physician immediately. Remove stomach contents by

gastric suction or induce vomiting only as directed by medical personnel.

Never give anything by mouth to an unconscious person.

Note 1

It generally cures to a demouldable state in 30 to 60 minutes; however, thin sections or certain part configurations may require more in-mould cure time. Sections that are less than 3mm may require more before demould. It depends on different products.

Note 2

Both components should be mixed before each use to ensure uniformity of the materials. Opened containers of material should be prevented moisture contamination from humid air.

Disclaimer

The data presented in this leaflet are in accordance with the present state of our knowledge, and does not absolve the user from carefully checking all supplies immediately on receipt. We reserve the right to alter product constants within the scope of technical progress or new developments. The recommendations made in this leaflet should be checked by preliminary trials because of conditions during processing over which we have no control, especially where other companies’ raw material are also being used. Recommendations for use do not constitute a warranty,

Either expressed or implied, of the fitness or suitability of the product for a particular purpose.